1

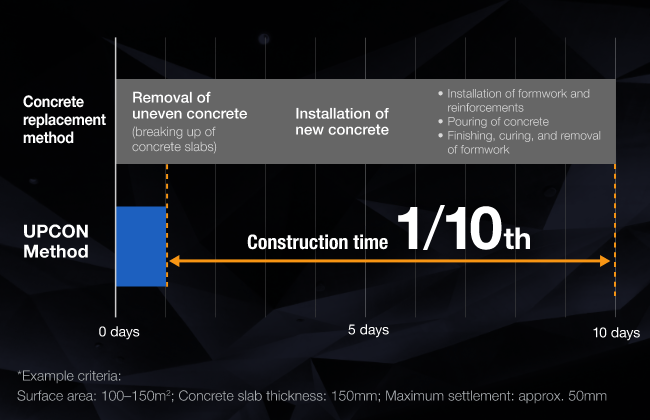

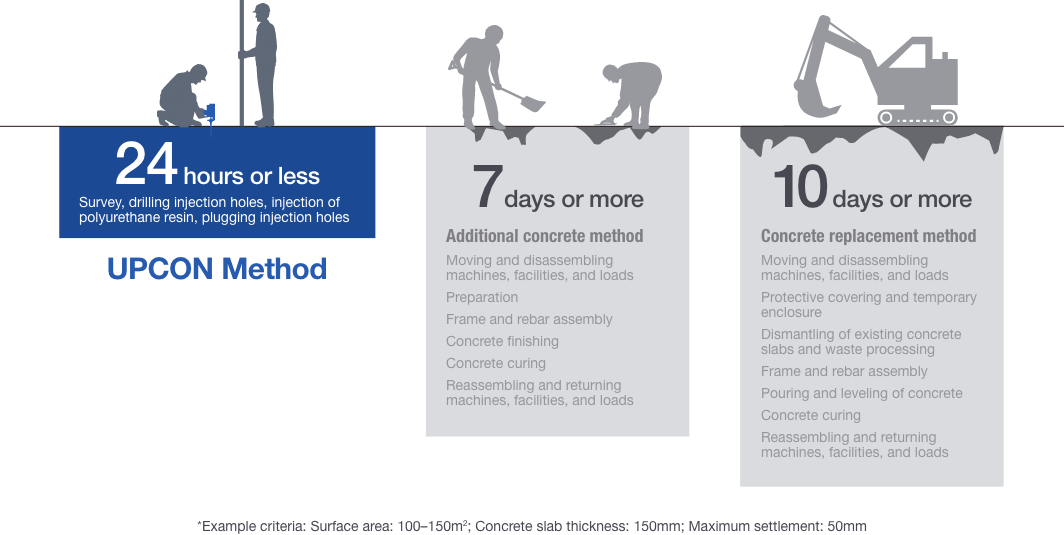

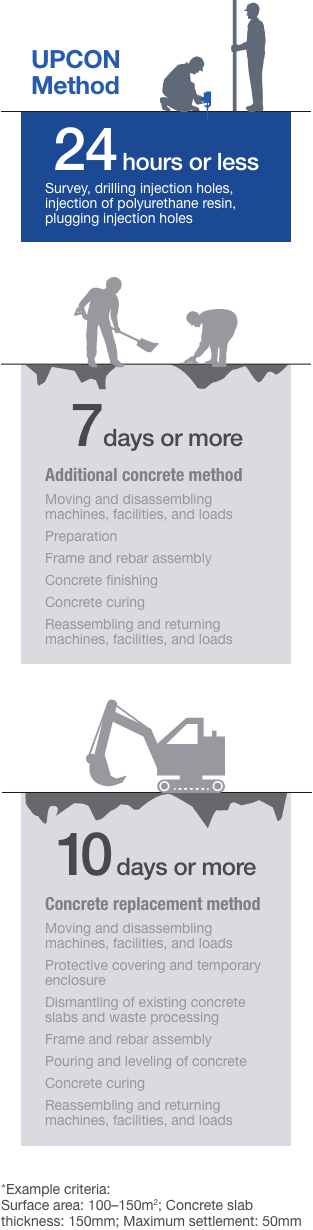

Short construction times

Construction work is completed in one-tenth the time of conventional methods

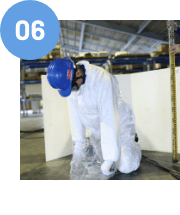

The UPCON Method does not require existing concrete floors to be demolished, nor does it require a curing period. For these reasons, compared to conventional methods, the UPCON Method requires significantly less construction time.